Application

Single jacket loose tube cable with a dielectric central strength member, reinforced with glass yarns and polyethylene jacket, designed for outdoor applications, for direct installations in duct. The cable is supplied in UV resistant high density polyethylene (HDPE) duct.

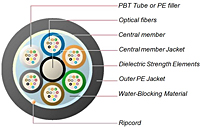

Construction

Up to 12 optical fibers are enclosed in a polybutylene terephthalate (PBT) tubes.

Up to 24 tubes are stranded around jacketed dielectric central member together with PE fillers to form the cable core.

The fibers and tubes are color coded for easy identification.

All the interstices in the cable core are filled with a water blocking materials to prevent water penetration. Water swelling glass yarns are laid over the cable core to serve as peripheral dielectric strength members.

A polyethylene jacket extruded over the glass yarns provides the final cable shape and protection. A ripcord is provided under the jacket to facilitate its removal.

The cable is inserted into UV resistant high density polyethylene duct for wide range of uses including extreme temperatures, abrasive and high tension applications in underground installations.

|

Cable Nominal Dimensions and Weight |

|||||||||

|

FIBER |

2-60 |

61-72 |

73-96 |

97-120 |

121-144 |

145-216 |

217-240 |

241-288 |

|

|

Cable |

inch |

0.4 |

0.42 |

0.49 |

0.56 |

0.62 |

0.61 |

0.64 |

0.71 |

|

mm |

10.1 |

10.7 |

12.5 |

14.1 |

15.7 |

15.4 |

16.2 |

18 |

|

|

Cable |

lb/kft |

47 |

53 |

69 |

97 |

112 |

97 |

109 |

134 |

|

kg/km |

70 |

79 |

103 |

145 |

166 |

145 |

162 |

200 |

|

|

|

|

|

Minimum bend radius with load |

15 x OD |

|

Temperature Range |

|

|

Installation |

-300C to 600C (-220F to 1400F) |

|

Fiber Characteristics |

||||

|

|

Type |

Single mode |

Multi mode |

|

|

PHYSICAL Characteristics |

|

|

50/125 |

62.5/125 |

|

Core Diameter |

µm |

|

50.0 ± 2.5 |

50.0 ± 2.5 |

|

Clad Diameter |

µm |

125.0 ± 0.7 |

125.0 ± 1.0 |

125.0 ± 1.0 |

|

Core/Clad Concentricity Error (Offset) |

µm |

≤ 0.5,<0.2 typical |

≤ 1.0 |

≤ 1.0 |

|

Coating diameter |

µm |

235-245 |

245 ± 10 |

245 ± 10 |

|

Tensile proof test |

kpsi |

100 |

100 |

100 |

|

OPTICAL CHARACTERISTICS |

|

|

|

|

|

Attenuation for Wavelength at 1310 nm |

dB/km |

≤0.34 (max), ≤0.32 typical |

|

|

|

Attenuation for Wavelength at 1550 nm |

dB/km |

≤0.21 (max), ≤0.19 typical |

|

|

|

Attenuation for Wavelength at 850 nm |

dB/km |

|

≤ 2.3 |

≤ 0.9 |

|

Attenuation for Wavelength at 1300 nm |

dB/km |

|

≤ 0.6 |

≤ 0.6 |

|

Zero Dispersion Wavelength (λ0) |

Nm |

1302-1322 |

1295-1340 |

1320-1365 |

|

MODE FIELD DIAMETER |

|

|

|

|

|

for wavelength 1310 nm |

µm |

9.2 ± 0.4 |

|

|

|

for wavelength 1550 nm |

µm |

10.4 ± 0.5 |

|

|

|

Cut-off wavelength (λcc) |

nm |

≤ 1260 |

|

|

|

Fibers and Tubes Color-Code per TIA/EIA 598A |

||||||||||||

|

FIBER |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

COLOR |

Blue |

Orange |

Green |

Brown |

Slate |

White |

Red |

Black |

Yellow |

Violet |

Rose |

Aqua |

Polyethylene Duct Characteristics

The duct is bent to a minimum (supported) radius of 10 outer diameters

Tests on finishing duct are performed in accordance with:

- ASTM D3035 Polyethylene Plastic Pipe Based on Controlled Outside Diameter

- ASTM D1248 Polyethylene Plastics Molding and Extrusion Materials (Type III, Class A, B or C, Category 5, grade P34)

- ASTM D1693 Environmental Stress Cracking of Ethylene Plastics (Cond. B, F20/96 HRS)

- ASTM D1238 Flow Rates of Thermoplastics by extrusion Plastometer

- ASTM D638 Tensile properties of Plastics

- ASTM D3350 Polyethylene Plastic Pipe and Fitting Materials (Cell #335440)

- NEMA TC 7 Smooth-wall Coilable Polyethylene Electrical Plastic Duct