PowerGuard® cables are intended for use in wet or dry locations for distribution of single or three phase medium-voltage power. These cables may be installed in ducts or direct buried.

Description

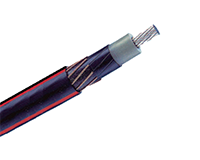

Single conductor cable with filled strand aluminum conductors, triple extruded dry cured insulation system consisting of a thermosetting semiconducting conductor shield, high dielectric strength PowerGuard® TRXLPE insulation, thermosetting semiconducting insulation shield, copper concentric neutral wires, water blocking agents, black encapsulating cross-linked polyethylene (TRXLPE) jacket.

Construction

Conductor: Class A or B concentric stranded aluminum alloy 1350 per ASTM B 231. Stranded conductors are water-blocked with conductor filling compound.

Conductor Shield: Extruded thermosetting semiconducting shield which is free stripping from the conductor and bonded to the insulation.

Insulation: Extruded, Tree-Retardant Cross-linked Polyethylene (TRXLPE) as defined in ANSI/ICEA S-94-649 - 100% insulation level.

Insulation Shield: Extruded thermosetting semiconducting shield with controlled adhesion to the insulation providing the required balance between electrical integrity and ease of stripping.

Metallic Shield: Solid bare copper wires helically applied and uniformly spaced.

Water-blocking agents: Applied over the insulation shield and around the neutral wires to resist longitudinal water penetration. Longitudinal water penetration shall be tested in accordance with the latest edition of ICEA T-34-664 except that the minimum requirement is 15 psig for 1 hour.

Outer jacket: An extruded-to-fill black non-conducting cross-linked polyethylene jacket, meeting the physical requirements the tables below, when tested by the methods specified in ANSI/ICEA S-94-649. The jacket shall be free-stripping and not interfere with contact between the neutral wires and the underlying extruded insulation shield. The jacket is sunlight resistant. The jacket shall contain a print legend marking, sequential length marking and three longitudinal extruded red stripes.

Designed for 40 years of service.

- Copper Conductors

- Black TRXLPE jacket with no stripes

- Multiplex cables

|

Physical Properties of Extruded-to-Fill XLPE Jacket

|

|

| Unaged Tensile Strength, min. (PSI) | 1500 |

| Aged* Tensile Strength, min. ret. (%) | 70 |

| Unaged Elongated, min. (%) | 150 |

| Aged* Elongated, min. ret. (%) | 70 |

| Heat Distortion 1 hr at 131 ºC, max. (%) | 30 |

| Insulation Temperature Rating | |

| Normal | 105º C |

| Emergency* | 140º C |

| Short Circuit - Shield | 250º C |

| Short Circuit - Conductor | 350º C |

Standards

- ASTM B-231 (Compact) or ASTM B-400 (Compressed)

- AEIC CS8

- ICEA S-94-649

- ICEA T-31-610

- ICEA T-34-664 as applicable for TRXLPE insulated concentric neutral cable

- UL 1072 MV-105

- CSA Standard C68.5-07 File # 257759 Primary Shielded and Concentric Neutral Cable for Distribution

NOTES

- Extruded layer thicknesses and insulation and insulation shield diameters are in accordance with ANSI/ICEA S-94-649 for concentric neutral cables rated 5-46 kV and also meet the requirements of the latest revisions of AEIC CS8. Dimensions and weights not designated as minimum or maximum are nominal values and are subject to manufacturing tolerances.

- Ampacities based on cables operating in a 3-phase installation with one cable per phase, flat spaced and touching, earth rho of 90ºC-cm/ W, earth ambient of 20ºC, neutral wires grounded at both ends, 75% and 100% load factor, conductor temperature of 105ºC, and 36" depth of burial.

Item # |

Conductor

|

Neutral

|

Conductor

|

Capacitance

|

8

|

8

|

16

|

16

|

24

|

24

|

|---|---|---|---|---|---|---|---|---|---|---|

| A1/0-01UD35GT101X |

Conductor AL Size AWG or kcmil N/A 1/0 |

Neutral Size N/A Full |

Conductor Resistance 20 °C Ohms/mft N/A 0.185 |

Capacitance µF/mft N/A 0.043 |

8 CYCLES (A) ________ CONDUCTOR N/A 12,974 |

8 CYCLES (A) ________ SHIELD N/A 11,764 |

16 CYCLES (A) ________ CONDUCTOR N/A 9,003 |

16 CYCLES (A) ________ SHIELD N/A 8,163 |

24 CYCLES (A) ________ CONDUCTOR N/A 7,396 |

24 CYCLES (A) ________ SHIELD N/A 6,706 |

| A1/0-01UD35GT203X |

Conductor AL Size AWG or kcmil N/A 1/0 |

Neutral Size N/A 2/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.185 |

Capacitance µF/mft N/A 0.043 |

8 CYCLES (A) ________ CONDUCTOR N/A 12,974 |

8 CYCLES (A) ________ SHIELD N/A 8,000 |

16 CYCLES (A) ________ CONDUCTOR N/A 9,003 |

16 CYCLES (A) ________ SHIELD N/A 5,551 |

24 CYCLES (A) ________ CONDUCTOR N/A 7,396 |

24 CYCLES (A) ________ SHIELD N/A 4,561 |

| A1/0-01UD35GT102X |

Conductor AL Size AWG or kcmil N/A 1/0 |

Neutral Size N/A 1/2 |

Conductor Resistance 20 °C Ohms/mft N/A 0.185 |

Capacitance µF/mft N/A 0.043 |

8 CYCLES (A) ________ CONDUCTOR N/A 12,974 |

8 CYCLES (A) ________ SHIELD N/A 6,154 |

16 CYCLES (A) ________ CONDUCTOR N/A 9,003 |

16 CYCLES (A) ________ SHIELD N/A 4,270 |

24 CYCLES (A) ________ CONDUCTOR N/A 7,396 |

24 CYCLES (A) ________ SHIELD N/A 3,508 |

| A1/0-01UD35GT103X |

Conductor AL Size AWG or kcmil N/A 1/0 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.185 |

Capacitance µF/mft N/A 0.043 |

8 CYCLES (A) ________ CONDUCTOR N/A 12,974 |

8 CYCLES (A) ________ SHIELD N/A 4,308 |

16 CYCLES (A) ________ CONDUCTOR N/A 9,003 |

16 CYCLES (A) ________ SHIELD N/A 2,989 |

24 CYCLES (A) ________ CONDUCTOR N/A 7,396 |

24 CYCLES (A) ________ SHIELD N/A 2,456 |

| A2/0-01UD35GT101X |

Conductor AL Size AWG or kcmil N/A 2/0 |

Neutral Size N/A Full |

Conductor Resistance 20 °C Ohms/mft N/A 0.143 |

Capacitance µF/mft N/A 0.047 |

8 CYCLES (A) ________ CONDUCTOR N/A 16,353 |

8 CYCLES (A) ________ SHIELD N/A 14,705 |

16 CYCLES (A) ________ CONDUCTOR N/A 11,347 |

16 CYCLES (A) ________ SHIELD N/A 10,204 |

24 CYCLES (A) ________ CONDUCTOR N/A 9,322 |

24 CYCLES (A) ________ SHIELD N/A 8,383 |

| A2/0-01UD35GT203X |

Conductor AL Size AWG or kcmil N/A 2/0 |

Neutral Size N/A 2/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.143 |

Capacitance µF/mft N/A 0.047 |

8 CYCLES (A) ________ CONDUCTOR N/A 16,353 |

8 CYCLES (A) ________ SHIELD N/A 9,846 |

16 CYCLES (A) ________ CONDUCTOR N/A 11,347 |

16 CYCLES (A) ________ SHIELD N/A 6,832 |

24 CYCLES (A) ________ CONDUCTOR N/A 9,322 |

24 CYCLES (A) ________ SHIELD N/A 5,613 |

| A2/0-01UD35GT102X |

Conductor AL Size AWG or kcmil N/A 2/0 |

Neutral Size N/A 1/2 |

Conductor Resistance 20 °C Ohms/mft N/A 0.143 |

Capacitance µF/mft N/A 0.047 |

8 CYCLES (A) ________ CONDUCTOR N/A 16,353 |

8 CYCLES (A) ________ SHIELD N/A 7,385 |

16 CYCLES (A) ________ CONDUCTOR N/A 11,347 |

16 CYCLES (A) ________ SHIELD N/A 5,124 |

24 CYCLES (A) ________ CONDUCTOR N/A 9,322 |

24 CYCLES (A) ________ SHIELD N/A 4,210 |

| A2/0-01UD35GT103X |

Conductor AL Size AWG or kcmil N/A 2/0 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.143 |

Capacitance µF/mft N/A 0.047 |

8 CYCLES (A) ________ CONDUCTOR N/A 16,353 |

8 CYCLES (A) ________ SHIELD N/A 5,538 |

16 CYCLES (A) ________ CONDUCTOR N/A 11,347 |

16 CYCLES (A) ________ SHIELD N/A 3,843 |

24 CYCLES (A) ________ CONDUCTOR N/A 9,322 |

24 CYCLES (A) ________ SHIELD N/A 3,157 |

| A3/0-01UD35GT101X |

Conductor AL Size AWG or kcmil N/A 3/0 |

Neutral Size N/A Full |

Conductor Resistance 20 °C Ohms/mft N/A 0.113 |

Capacitance µF/mft N/A 0.049 |

8 CYCLES (A) ________ CONDUCTOR N/A 20,616 |

8 CYCLES (A) ________ SHIELD N/A 18,626 |

16 CYCLES (A) ________ CONDUCTOR N/A 14,305 |

16 CYCLES (A) ________ SHIELD N/A 12,924 |

24 CYCLES (A) ________ CONDUCTOR N/A 11,753 |

24 CYCLES (A) ________ SHIELD N/A 10,619 |

| A3/0-01UD35GT203X |

Conductor AL Size AWG or kcmil N/A 3/0 |

Neutral Size N/A 2/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.113 |

Capacitance µF/mft N/A 0.049 |

8 CYCLES (A) ________ CONDUCTOR N/A 20,616 |

8 CYCLES (A) ________ SHIELD N/A 12,744 |

16 CYCLES (A) ________ CONDUCTOR N/A 14,305 |

16 CYCLES (A) ________ SHIELD N/A 8,843 |

24 CYCLES (A) ________ CONDUCTOR N/A 11,753 |

24 CYCLES (A) ________ SHIELD N/A 7,265 |

| A3/0-01UD35GT102X |

Conductor AL Size AWG or kcmil N/A 3/0 |

Neutral Size N/A 1/2 |

Conductor Resistance 20 °C Ohms/mft N/A 0.113 |

Capacitance µF/mft N/A 0.049 |

8 CYCLES (A) ________ CONDUCTOR N/A 20,616 |

8 CYCLES (A) ________ SHIELD N/A 9,231 |

16 CYCLES (A) ________ CONDUCTOR N/A 14,305 |

16 CYCLES (A) ________ SHIELD N/A 6,405 |

24 CYCLES (A) ________ CONDUCTOR N/A 11,753 |

24 CYCLES (A) ________ SHIELD N/A 5,262 |

| A3/0-01UD35GT103X |

Conductor AL Size AWG or kcmil N/A 3/0 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.113 |

Capacitance µF/mft N/A 0.049 |

8 CYCLES (A) ________ CONDUCTOR N/A 20,616 |

8 CYCLES (A) ________ SHIELD N/A 6,769 |

16 CYCLES (A) ________ CONDUCTOR N/A 14,305 |

16 CYCLES (A) ________ SHIELD N/A 4,697 |

24 CYCLES (A) ________ CONDUCTOR N/A 11,753 |

24 CYCLES (A) ________ SHIELD N/A 3,859 |

| A4/0-01UD35GT101X |

Conductor AL Size AWG or kcmil N/A 4/0 |

Neutral Size N/A Full |

Conductor Resistance 20 °C Ohms/mft N/A 0.088 |

Capacitance µF/mft N/A 0.053 |

8 CYCLES (A) ________ CONDUCTOR N/A 25,997 |

8 CYCLES (A) ________ SHIELD N/A 22,547 |

16 CYCLES (A) ________ CONDUCTOR N/A 18,039 |

16 CYCLES (A) ________ SHIELD N/A 15,645 |

24 CYCLES (A) ________ CONDUCTOR N/A 14,821 |

24 CYCLES (A) ________ SHIELD N/A 12,854 |

| A4/0-01UD35GT203X |

Conductor AL Size AWG or kcmil N/A 4/0 |

Neutral Size N/A 2/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.088 |

Capacitance µF/mft N/A 0.053 |

8 CYCLES (A) ________ CONDUCTOR N/A 25,997 |

8 CYCLES (A) ________ SHIELD N/A 14,705 |

16 CYCLES (A) ________ CONDUCTOR N/A 18,039 |

16 CYCLES (A) ________ SHIELD N/A 10,204 |

24 CYCLES (A) ________ CONDUCTOR N/A 14,821 |

24 CYCLES (A) ________ SHIELD N/A 8,383 |

| A4/0-01UD35GT102X |

Conductor AL Size AWG or kcmil N/A 4/0 |

Neutral Size N/A 1/2 |

Conductor Resistance 20 °C Ohms/mft N/A 0.088 |

Capacitance µF/mft N/A 0.053 |

8 CYCLES (A) ________ CONDUCTOR N/A 25,997 |

8 CYCLES (A) ________ SHIELD N/A 11,764 |

16 CYCLES (A) ________ CONDUCTOR N/A 18,039 |

16 CYCLES (A) ________ SHIELD N/A 8,163 |

24 CYCLES (A) ________ CONDUCTOR N/A 14,821 |

24 CYCLES (A) ________ SHIELD N/A 6,706 |

| A4/0-01UD35GT103X |

Conductor AL Size AWG or kcmil N/A 4/0 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.088 |

Capacitance µF/mft N/A 0.053 |

8 CYCLES (A) ________ CONDUCTOR N/A 25,997 |

8 CYCLES (A) ________ SHIELD N/A 7,843 |

16 CYCLES (A) ________ CONDUCTOR N/A 18,039 |

16 CYCLES (A) ________ SHIELD N/A 5,442 |

24 CYCLES (A) ________ CONDUCTOR N/A 14,821 |

24 CYCLES (A) ________ SHIELD N/A 4,471 |

| A4/0-01UD35GT103X1 |

Conductor AL Size AWG or kcmil N/A 4/0 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.088 |

Capacitance µF/mft N/A 0.053 |

8 CYCLES (A) ________ CONDUCTOR N/A 25,997 |

8 CYCLES (A) ________ SHIELD N/A 10,784 |

16 CYCLES (A) ________ CONDUCTOR N/A 18,039 |

16 CYCLES (A) ________ SHIELD N/A 7,483 |

24 CYCLES (A) ________ CONDUCTOR N/A 14,821 |

24 CYCLES (A) ________ SHIELD N/A 6,148 |

| A4/0-01UD35GT106X |

Conductor AL Size AWG or kcmil N/A 4/0 |

Neutral Size N/A 1/6 |

Conductor Resistance 20 °C Ohms/mft N/A 0.088 |

Capacitance µF/mft N/A 0.053 |

8 CYCLES (A) ________ CONDUCTOR N/A 25,997 |

8 CYCLES (A) ________ SHIELD N/A 5,538 |

16 CYCLES (A) ________ CONDUCTOR N/A 18,039 |

16 CYCLES (A) ________ SHIELD N/A 3,843 |

24 CYCLES (A) ________ CONDUCTOR N/A 14,821 |

24 CYCLES (A) ________ SHIELD N/A 3,157 |

| A250-01UD35GT101X |

Conductor AL Size AWG or kcmil N/A 250 |

Neutral Size N/A Full |

Conductor Resistance 20 °C Ohms/mft N/A 0.074 |

Capacitance µF/mft N/A 0.056 |

8 CYCLES (A) ________ CONDUCTOR N/A 30,715 |

8 CYCLES (A) ________ SHIELD N/A 39,614 |

16 CYCLES (A) ________ CONDUCTOR N/A 21,313 |

16 CYCLES (A) ________ SHIELD N/A 27,487 |

24 CYCLES (A) ________ CONDUCTOR N/A 17,510 |

24 CYCLES (A) ________ SHIELD N/A 22,583 |

| A250-01UD35GT203X |

Conductor AL Size AWG or kcmil N/A 250 |

Neutral Size N/A 2/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.074 |

Capacitance µF/mft N/A 0.056 |

8 CYCLES (A) ________ CONDUCTOR N/A 30,715 |

8 CYCLES (A) ________ SHIELD N/A 18,626 |

16 CYCLES (A) ________ CONDUCTOR N/A 21,313 |

16 CYCLES (A) ________ SHIELD N/A 12,924 |

24 CYCLES (A) ________ CONDUCTOR N/A 17,510 |

24 CYCLES (A) ________ SHIELD N/A 10,619 |

| A250-01UD35GT102X |

Conductor AL Size AWG or kcmil N/A 250 |

Neutral Size N/A 1/2 |

Conductor Resistance 20 °C Ohms/mft N/A 0.074 |

Capacitance µF/mft N/A 0.056 |

8 CYCLES (A) ________ CONDUCTOR N/A 30,715 |

8 CYCLES (A) ________ SHIELD N/A 13,725 |

16 CYCLES (A) ________ CONDUCTOR N/A 21,313 |

16 CYCLES (A) ________ SHIELD N/A 9,523 |

24 CYCLES (A) ________ CONDUCTOR N/A 17,510 |

24 CYCLES (A) ________ SHIELD N/A 7,824 |

| A250-01UD35GT103X |

Conductor AL Size AWG or kcmil N/A 250 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.074 |

Capacitance µF/mft N/A 0.056 |

8 CYCLES (A) ________ CONDUCTOR N/A 30,715 |

8 CYCLES (A) ________ SHIELD N/A 9,803 |

16 CYCLES (A) ________ CONDUCTOR N/A 21,313 |

16 CYCLES (A) ________ SHIELD N/A 6,802 |

24 CYCLES (A) ________ CONDUCTOR N/A 17,510 |

24 CYCLES (A) ________ SHIELD N/A 5,589 |

| A250-01UD35GT106X |

Conductor AL Size AWG or kcmil N/A 250 |

Neutral Size N/A 1/6 |

Conductor Resistance 20 °C Ohms/mft N/A 0.074 |

Capacitance µF/mft N/A 0.056 |

8 CYCLES (A) ________ CONDUCTOR N/A 30,715 |

8 CYCLES (A) ________ SHIELD N/A 4,923 |

16 CYCLES (A) ________ CONDUCTOR N/A 21,313 |

16 CYCLES (A) ________ SHIELD N/A 3,416 |

24 CYCLES (A) ________ CONDUCTOR N/A 17,510 |

24 CYCLES (A) ________ SHIELD N/A 2,807 |

| A250-01UD35GT112X |

Conductor AL Size AWG or kcmil N/A 250 |

Neutral Size N/A 1/12 |

Conductor Resistance 20 °C Ohms/mft N/A 0.074 |

Capacitance µF/mft N/A 0.056 |

8 CYCLES (A) ________ CONDUCTOR N/A 30,715 |

8 CYCLES (A) ________ SHIELD N/A 3,692 |

16 CYCLES (A) ________ CONDUCTOR N/A 21,313 |

16 CYCLES (A) ________ SHIELD N/A 2,562 |

24 CYCLES (A) ________ CONDUCTOR N/A 17,510 |

24 CYCLES (A) ________ SHIELD N/A 2,105 |

| A350-01UD35GT101X |

Conductor AL Size AWG or kcmil N/A 350 |

Neutral Size N/A Full |

Conductor Resistance 20 °C Ohms/mft N/A 0.053 |

Capacitance µF/mft N/A 0.062 |

8 CYCLES (A) ________ CONDUCTOR N/A 43,001 |

8 CYCLES (A) ________ SHIELD N/A 39,614 |

16 CYCLES (A) ________ CONDUCTOR N/A 29,838 |

16 CYCLES (A) ________ SHIELD N/A 27,487 |

24 CYCLES (A) ________ CONDUCTOR N/A 24,514 |

24 CYCLES (A) ________ SHIELD N/A 22,583 |

| A350-01UD35GT203X |

Conductor AL Size AWG or kcmil N/A 350 |

Neutral Size N/A 2/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.053 |

Capacitance µF/mft N/A 0.062 |

8 CYCLES (A) ________ CONDUCTOR N/A 43,001 |

8 CYCLES (A) ________ SHIELD N/A 24,921 |

16 CYCLES (A) ________ CONDUCTOR N/A 29,838 |

16 CYCLES (A) ________ SHIELD N/A 17,292 |

24 CYCLES (A) ________ CONDUCTOR N/A 24,514 |

24 CYCLES (A) ________ SHIELD N/A 14,207 |

| A350-01UD35GT102X |

Conductor AL Size AWG or kcmil N/A 350 |

Neutral Size N/A 1/2 |

Conductor Resistance 20 °C Ohms/mft N/A 0.053 |

Capacitance µF/mft N/A 0.062 |

8 CYCLES (A) ________ CONDUCTOR N/A 43,001 |

8 CYCLES (A) ________ SHIELD N/A 19,606 |

16 CYCLES (A) ________ CONDUCTOR N/A 29,838 |

16 CYCLES (A) ________ SHIELD N/A 13,605 |

24 CYCLES (A) ________ CONDUCTOR N/A 24,514 |

24 CYCLES (A) ________ SHIELD N/A 11,177 |

| A350-01UD35GT103X |

Conductor AL Size AWG or kcmil N/A 350 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.053 |

Capacitance µF/mft N/A 0.062 |

8 CYCLES (A) ________ CONDUCTOR N/A 43,001 |

8 CYCLES (A) ________ SHIELD N/A 12,744 |

16 CYCLES (A) ________ CONDUCTOR N/A 29,838 |

16 CYCLES (A) ________ SHIELD N/A 8,843 |

24 CYCLES (A) ________ CONDUCTOR N/A 24,514 |

24 CYCLES (A) ________ SHIELD N/A 7,265 |

| A350-01UD35GT106X |

Conductor AL Size AWG or kcmil N/A 350 |

Neutral Size N/A 1/6 |

Conductor Resistance 20 °C Ohms/mft N/A 0.053 |

Capacitance µF/mft N/A 0.062 |

8 CYCLES (A) ________ CONDUCTOR N/A 43,001 |

8 CYCLES (A) ________ SHIELD N/A 6,769 |

16 CYCLES (A) ________ CONDUCTOR N/A 29,838 |

16 CYCLES (A) ________ SHIELD N/A 4,697 |

24 CYCLES (A) ________ CONDUCTOR N/A 24,514 |

24 CYCLES (A) ________ SHIELD N/A 3,859 |

| A350-01UD35GT112X |

Conductor AL Size AWG or kcmil N/A 350 |

Neutral Size N/A 1/12 |

Conductor Resistance 20 °C Ohms/mft N/A 0.053 |

Capacitance µF/mft N/A 0.062 |

8 CYCLES (A) ________ CONDUCTOR N/A 43,001 |

8 CYCLES (A) ________ SHIELD N/A 4,308 |

16 CYCLES (A) ________ CONDUCTOR N/A 29,838 |

16 CYCLES (A) ________ SHIELD N/A 2,989 |

24 CYCLES (A) ________ CONDUCTOR N/A 24,514 |

24 CYCLES (A) ________ SHIELD N/A 2,456 |

| A500-01UD35GT203X |

Conductor AL Size AWG or kcmil N/A 500 |

Neutral Size N/A 2/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.036 |

Capacitance µF/mft N/A 0.071 |

8 CYCLES (A) ________ CONDUCTOR N/A 62,597 |

8 CYCLES (A) ________ SHIELD N/A 35,823 |

16 CYCLES (A) ________ CONDUCTOR N/A 43,435 |

16 CYCLES (A) ________ SHIELD N/A 24,858 |

24 CYCLES (A) ________ CONDUCTOR N/A 35,685 |

24 CYCLES (A) ________ SHIELD N/A 20,423 |

| A500-01UD35GT102X |

Conductor AL Size AWG or kcmil N/A 500 |

Neutral Size N/A 1/2 |

Conductor Resistance 20 °C Ohms/mft N/A 0.036 |

Capacitance µF/mft N/A 0.071 |

8 CYCLES (A) ________ CONDUCTOR N/A 62,597 |

8 CYCLES (A) ________ SHIELD N/A 28,036 |

16 CYCLES (A) ________ CONDUCTOR N/A 43,435 |

16 CYCLES (A) ________ SHIELD N/A 19,454 |

24 CYCLES (A) ________ CONDUCTOR N/A 35,685 |

24 CYCLES (A) ________ SHIELD N/A 15,983 |

| A500-01UD35GT103X |

Conductor AL Size AWG or kcmil N/A 500 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.036 |

Capacitance µF/mft N/A 0.071 |

8 CYCLES (A) ________ CONDUCTOR N/A 62,597 |

8 CYCLES (A) ________ SHIELD N/A 18,691 |

16 CYCLES (A) ________ CONDUCTOR N/A 43,435 |

16 CYCLES (A) ________ SHIELD N/A 12,969 |

24 CYCLES (A) ________ CONDUCTOR N/A 35,685 |

24 CYCLES (A) ________ SHIELD N/A 10,655 |

| A500-01UD35GT106X |

Conductor AL Size AWG or kcmil N/A 500 |

Neutral Size N/A 1/6 |

Conductor Resistance 20 °C Ohms/mft N/A 0.036 |

Capacitance µF/mft N/A 0.071 |

8 CYCLES (A) ________ CONDUCTOR N/A 62,597 |

8 CYCLES (A) ________ SHIELD N/A 9,803 |

16 CYCLES (A) ________ CONDUCTOR N/A 43,435 |

16 CYCLES (A) ________ SHIELD N/A 6,802 |

24 CYCLES (A) ________ CONDUCTOR N/A 35,685 |

24 CYCLES (A) ________ SHIELD N/A 5,589 |

| A500-01UD35GT112X |

Conductor AL Size AWG or kcmil N/A 500 |

Neutral Size N/A 1/12 |

Conductor Resistance 20 °C Ohms/mft N/A 0.036 |

Capacitance µF/mft N/A 0.071 |

8 CYCLES (A) ________ CONDUCTOR N/A 62,597 |

8 CYCLES (A) ________ SHIELD N/A 6,154 |

16 CYCLES (A) ________ CONDUCTOR N/A 43,435 |

16 CYCLES (A) ________ SHIELD N/A 4,270 |

24 CYCLES (A) ________ CONDUCTOR N/A 35,685 |

24 CYCLES (A) ________ SHIELD N/A 3,508 |

| A750-01UD35GT102X |

Conductor AL Size AWG or kcmil N/A 750 |

Neutral Size N/A 1/2 |

Conductor Resistance 20 °C Ohms/mft N/A 0.025 |

Capacitance µF/mft N/A 0.082 |

8 CYCLES (A) ________ CONDUCTOR N/A 92,145 |

8 CYCLES (A) ________ SHIELD N/A 42,089 |

16 CYCLES (A) ________ CONDUCTOR N/A 63,938 |

16 CYCLES (A) ________ SHIELD N/A 29,205 |

24 CYCLES (A) ________ CONDUCTOR N/A 52,531 |

24 CYCLES (A) ________ SHIELD N/A 23,995 |

| A750-01UD35GT103X |

Conductor AL Size AWG or kcmil N/A 750 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.025 |

Capacitance µF/mft N/A 0.082 |

8 CYCLES (A) ________ CONDUCTOR N/A 92,145 |

8 CYCLES (A) ________ SHIELD N/A 28,036 |

16 CYCLES (A) ________ CONDUCTOR N/A 63,938 |

16 CYCLES (A) ________ SHIELD N/A 19,454 |

24 CYCLES (A) ________ CONDUCTOR N/A 52,531 |

24 CYCLES (A) ________ SHIELD N/A 15,983 |

| A750-01UD35GT106X |

Conductor AL Size AWG or kcmil N/A 750 |

Neutral Size N/A 1/6 |

Conductor Resistance 20 °C Ohms/mft N/A 0.025 |

Capacitance µF/mft N/A 0.082 |

8 CYCLES (A) ________ CONDUCTOR N/A 92,145 |

8 CYCLES (A) ________ SHIELD N/A 13,725 |

16 CYCLES (A) ________ CONDUCTOR N/A 63,938 |

16 CYCLES (A) ________ SHIELD N/A 9,523 |

24 CYCLES (A) ________ CONDUCTOR N/A 52,531 |

24 CYCLES (A) ________ SHIELD N/A 7,824 |

| A750-01UD35GT112X |

Conductor AL Size AWG or kcmil N/A 750 |

Neutral Size N/A 1/12 |

Conductor Resistance 20 °C Ohms/mft N/A 0.025 |

Capacitance µF/mft N/A 0.082 |

8 CYCLES (A) ________ CONDUCTOR N/A 92,145 |

8 CYCLES (A) ________ SHIELD N/A 9,231 |

16 CYCLES (A) ________ CONDUCTOR N/A 63,938 |

16 CYCLES (A) ________ SHIELD N/A 6,405 |

24 CYCLES (A) ________ CONDUCTOR N/A 52,531 |

24 CYCLES (A) ________ SHIELD N/A 5,262 |

| A1000-01UD35GT102X |

Conductor AL Size AWG or kcmil N/A 1000 |

Neutral Size N/A 1/2 |

Conductor Resistance 20 °C Ohms/mft N/A 0.018 |

Capacitance µF/mft N/A 0.091 |

8 CYCLES (A) ________ CONDUCTOR N/A 122,860 |

8 CYCLES (A) ________ SHIELD N/A 54,469 |

16 CYCLES (A) ________ CONDUCTOR N/A 85,251 |

16 CYCLES (A) ________ SHIELD N/A 37,795 |

24 CYCLES (A) ________ CONDUCTOR N/A 70,041 |

24 CYCLES (A) ________ SHIELD N/A 31,052 |

| A1000-01UD35GT103X |

Conductor AL Size AWG or kcmil N/A 1000 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.018 |

Capacitance µF/mft N/A 0.091 |

8 CYCLES (A) ________ CONDUCTOR N/A 122,860 |

8 CYCLES (A) ________ SHIELD N/A 35,823 |

16 CYCLES (A) ________ CONDUCTOR N/A 85,251 |

16 CYCLES (A) ________ SHIELD N/A 24,858 |

24 CYCLES (A) ________ CONDUCTOR N/A 70,041 |

24 CYCLES (A) ________ SHIELD N/A 20,423 |

| A1000-01UD35GT106X |

Conductor AL Size AWG or kcmil N/A 1000 |

Neutral Size N/A 1/6 |

Conductor Resistance 20 °C Ohms/mft N/A 0.018 |

Capacitance µF/mft N/A 0.091 |

8 CYCLES (A) ________ CONDUCTOR N/A 122,860 |

8 CYCLES (A) ________ SHIELD N/A 18,691 |

16 CYCLES (A) ________ CONDUCTOR N/A 85,251 |

16 CYCLES (A) ________ SHIELD N/A 12,969 |

24 CYCLES (A) ________ CONDUCTOR N/A 70,041 |

24 CYCLES (A) ________ SHIELD N/A 10,655 |

| A1000-01UD35GT112X |

Conductor AL Size AWG or kcmil N/A 1000 |

Neutral Size N/A 1/12 |

Conductor Resistance 20 °C Ohms/mft N/A 0.018 |

Capacitance µF/mft N/A 0.091 |

8 CYCLES (A) ________ CONDUCTOR N/A 122,860 |

8 CYCLES (A) ________ SHIELD N/A 9,803 |

16 CYCLES (A) ________ CONDUCTOR N/A 85,251 |

16 CYCLES (A) ________ SHIELD N/A 6,802 |

24 CYCLES (A) ________ CONDUCTOR N/A 70,041 |

24 CYCLES (A) ________ SHIELD N/A 5,589 |

| A1000-01UD35GT106X1 |

Conductor AL Size AWG or kcmil N/A 1000 |

Neutral Size N/A 1/6 |

Conductor Resistance 20 °C Ohms/mft N/A 0.018 |

Capacitance µF/mft N/A 0.091 |

8 CYCLES (A) ________ CONDUCTOR N/A 122,860 |

8 CYCLES (A) ________ SHIELD N/A 24,921 |

16 CYCLES (A) ________ CONDUCTOR N/A 85,251 |

16 CYCLES (A) ________ SHIELD N/A 17,292 |

24 CYCLES (A) ________ CONDUCTOR N/A 70,041 |

24 CYCLES (A) ________ SHIELD N/A 14,207 |

| A1250-01UD35GT103X |

Conductor AL Size AWG or kcmil N/A 1250 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.014 |

Capacitance µF/mft N/A 0.099 |

8 CYCLES (A) ________ CONDUCTOR N/A 153,575 |

8 CYCLES (A) ________ SHIELD N/A 44,565 |

16 CYCLES (A) ________ CONDUCTOR N/A 106,564 |

16 CYCLES (A) ________ SHIELD N/A 30,923 |

24 CYCLES (A) ________ CONDUCTOR N/A 87,551 |

24 CYCLES (A) ________ SHIELD N/A 25,406 |

| A1250-01UD35GT106X |

Conductor AL Size AWG or kcmil N/A 1250 |

Neutral Size N/A 1/6 |

Conductor Resistance 20 °C Ohms/mft N/A 0.014 |

Capacitance µF/mft N/A 0.099 |

8 CYCLES (A) ________ CONDUCTOR N/A 153,575 |

8 CYCLES (A) ________ SHIELD N/A 23,363 |

16 CYCLES (A) ________ CONDUCTOR N/A 106,564 |

16 CYCLES (A) ________ SHIELD N/A 16,211 |

24 CYCLES (A) ________ CONDUCTOR N/A 87,551 |

24 CYCLES (A) ________ SHIELD N/A 13,319 |

| A1250-01UD35GT112X |

Conductor AL Size AWG or kcmil N/A 1250 |

Neutral Size N/A 1/12 |

Conductor Resistance 20 °C Ohms/mft N/A 0.014 |

Capacitance µF/mft N/A 0.099 |

8 CYCLES (A) ________ CONDUCTOR N/A 153,575 |

8 CYCLES (A) ________ SHIELD N/A 11,764 |

16 CYCLES (A) ________ CONDUCTOR N/A 106,564 |

16 CYCLES (A) ________ SHIELD N/A 8,163 |

24 CYCLES (A) ________ CONDUCTOR N/A 87,551 |

24 CYCLES (A) ________ SHIELD N/A 6,706 |

| A1500-01UD35GT103X |

Conductor AL Size AWG or kcmil N/A 1500 |

Neutral Size N/A 1/3 |

Conductor Resistance 20 °C Ohms/mft N/A 0.012 |

Capacitance µF/mft N/A 0.107 |

8 CYCLES (A) ________ CONDUCTOR N/A 184,290 |

8 CYCLES (A) ________ SHIELD N/A 54,469 |

16 CYCLES (A) ________ CONDUCTOR N/A 127,877 |

16 CYCLES (A) ________ SHIELD N/A 37,795 |

24 CYCLES (A) ________ CONDUCTOR N/A 105,061 |

24 CYCLES (A) ________ SHIELD N/A 31,052 |

| A1500-01UD35GT106X |

Conductor AL Size AWG or kcmil N/A 1500 |

Neutral Size N/A 1/6 |

Conductor Resistance 20 °C Ohms/mft N/A 0.012 |

Capacitance µF/mft N/A 0.107 |

8 CYCLES (A) ________ CONDUCTOR N/A 184,290 |

8 CYCLES (A) ________ SHIELD N/A 28,036 |

16 CYCLES (A) ________ CONDUCTOR N/A 127,877 |

16 CYCLES (A) ________ SHIELD N/A 19,454 |

24 CYCLES (A) ________ CONDUCTOR N/A 105,061 |

24 CYCLES (A) ________ SHIELD N/A 15,983 |

| A1500-01UD35GT112X |

Conductor AL Size AWG or kcmil N/A 1500 |

Neutral Size N/A 1/12 |

Conductor Resistance 20 °C Ohms/mft N/A 0.012 |

Capacitance µF/mft N/A 0.107 |

8 CYCLES (A) ________ CONDUCTOR N/A 184,290 |

8 CYCLES (A) ________ SHIELD N/A 13,725 |

16 CYCLES (A) ________ CONDUCTOR N/A 127,877 |

16 CYCLES (A) ________ SHIELD N/A 9,523 |

24 CYCLES (A) ________ CONDUCTOR N/A 105,061 |

24 CYCLES (A) ________ SHIELD N/A 7,824 |