Applications

PowerGuard® cables are intended for use in wet or dry locations for distribution of single or three phase medium-voltage power. These cables may be installed in ducts or direct buried.

Description

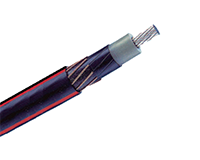

Single conductor cable with filled strand aluminum conductors, triple extruded dry cured insulation system consisting of a thermosetting semiconducting conductor shield, high dielectric strength PowerGuard® TRXLPE insulation, thermosetting semiconducting insulation shield, copper concentric neutral wires, water blocking agents, black encapsulating cross-linked polyethylene (XLPE) jacket.

Construction

Conductor: Class A or B Compressed concentric stranded aluminum alloy 1350 per ASTM B 231. Stranded conductors are water-blocked with conductor filling compound.

Conductor Shield: Extruded thermosetting semiconducting shield which is free stripping from the conductor and bonded to the insulation.

Insulation: Extruded, Tree-Retardant Cross-linked Polyethylene (TRXLPE) as defined in ANSI/ICEA S- 94-649 – 100% insulation level.

Insulation Shield: Extruded thermosetting semiconducting shield with controlled adhesion to the insulation providing the required balance between electrical integrity and ease of stripping.

Metallic Shield: Solid bare copper wires helically applied and uniformly spaced.

Water Block: Water-blocking agents applied over the insulation shield and around the neutral wires to resist longitudinal water penetration. Longitudinal water penetration shall be tested in accordance with the latest edition of ICEA T-34-664 except that the minimum requirement is 15 psig for 1 hour.

Jacket: Black insulating sunlight resistant cross linked polyethylene encapsulating the neutral wires with three extruded red stripes and NESC lightning bolt symbol.

Physical Properties of Extruded-to-Fill XLPE Jacket

• Unaged Tensile Strength, min. (PSI) ...........1500

• Aged* Tensile Strength, min. ret. (%) ............70

• Unaged Elongated, min. (%) .......................150

• Aged* Elongated, min. ret. (%)......................70

• Heat Distortion 1 hr at 131 ºC, max. (%)..........3

* Aged for 168 hrs at 121 ºC

Insulation Temperature Rating

Normal . . . . . . . . . . . . . . . . . . . . . . . . . . .105°C

Emergency* . . . . . . . . . . . . . . . . . . . . . . .140°C

Short Circuit . . . . . . . . . . . . . . . . . . . . . . .250°C

*Operation at the emergency overload temperature shall not exceed 1500 hours cumulative during the lifetime of the cable.

Standards

•AEIC CS8

•ICEA S-94-649

•ICEA T-31-610

•ICEA T-34-664 as applicable for TRXLPE insulated concentric neutral cable

•UL 1072 MV-105

Item # |

Conductor

|

No

|

Nominal

|

Neutral

|

Neutral

|

Neutral

|

TRXLPE

|

TRXLPE

|

TRXLPE

|

Encap

|

Encap

|

Neutral

|

Net

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A2-01UD15GT100X |

Conductor Size AWG/kcmil N/A 2 |

No of Wires N/A 7 |

Nominal Diameter (in) N/A 0.283 |

Neutral Size AWG/kcmil N/A 10 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A Full |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.649 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.729 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.037 |

Neutral lbs/MFT N/A 129 |

Net lbs/MFT N/A 583 |

| A1/0-01UD15GT100X |

Conductor Size AWG/kcmil N/A 1/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.362 |

Neutral Size AWG/kcmil N/A 12 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A Full |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.728 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.808 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.116 |

Neutral lbs/MFT N/A 154 |

Net lbs/MFT N/A 651 |

| A1/0-01UD15GT203X |

Conductor Size AWG/kcmil N/A 1/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.362 |

Neutral Size AWG/kcmil N/A 13 |

Neutral No. of Wires N/A 16 |

Neutral Size N/A 2/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.728 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.808 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.090 |

Neutral lbs/MFT N/A 105 |

Net lbs/MFT N/A 585 |

| A1/0-01UD15GT112X |

Conductor Size AWG/kcmil N/A 1/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.362 |

Neutral Size AWG/kcmil N/A 10 |

Neutral No. of Wires N/A 16 |

Neutral Size N/A 1/2 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.728 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.808 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.090 |

Neutral lbs/MFT N/A 81 |

Net lbs/MFT N/A 563 |

| A1/0-01UD15GT103X |

Conductor Size AWG/kcmil N/A 1/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.362 |

Neutral Size AWG/kcmil N/A 7 |

Neutral No. of Wires N/A 16 |

Neutral Size N/A 1/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.728 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.808 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.090 |

Neutral lbs/MFT N/A 57 |

Net lbs/MFT N/A 541 |

| A2/0-01UD15GT100X |

Conductor Size AWG/kcmil N/A 2/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.406 |

Neutral Size AWG/kcmil N/A 15 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A Full |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.772 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.852 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.160 |

Neutral lbs/MFT N/A 193 |

Net lbs/MFT N/A 737 |

| A2/0-01UD15GT103X |

Conductor Size AWG/kcmil N/A 2/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.406 |

Neutral Size AWG/kcmil N/A 16 |

Neutral No. of Wires N/A 16 |

Neutral Size N/A 2/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.772 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.852 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.134 |

Neutral lbs/MFT N/A 129 |

Net lbs/MFT N/A 657 |

| A2/0-01UD15GT103X |

Conductor Size AWG/kcmil N/A 2/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.406 |

Neutral Size AWG/kcmil N/A 12 |

Neutral No. of Wires N/A 16 |

Neutral Size N/A 1/2 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.772 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.852 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.134 |

Neutral lbs/MFT N/A 97 |

Net lbs/MFT N/A 628 |

| A2/0-01UD15GT103X |

Conductor Size AWG/kcmil N/A 2/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.406 |

Neutral Size AWG/kcmil N/A 9 |

Neutral No. of Wires N/A 16 |

Neutral Size N/A 1/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.772 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.852 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.134 |

Neutral lbs/MFT N/A 73 |

Net lbs/MFT N/A 605 |

| A3/0-01UD15GT203X |

Conductor Size AWG/kcmil N/A 3/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.456 |

Neutral Size AWG/kcmil N/A 19 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A Full |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.822 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.902 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.210 |

Neutral lbs/MFT N/A 244 |

Net lbs/MFT N/A 844 |

| A3/0-01UD15GT100X |

Conductor Size AWG/kcmil N/A 3/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.456 |

Neutral Size AWG/kcmil N/A 13 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 2/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.822 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.902 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.210 |

Neutral lbs/MFT N/A 167 |

Net lbs/MFT N/A 774 |

| A3/0-01UD15GT103X |

Conductor Size AWG/kcmil N/A 3/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.456 |

Neutral Size AWG/kcmil N/A 15 |

Neutral No. of Wires N/A 16 |

Neutral Size N/A 1/2 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.822 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.902 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.184 |

Neutral lbs/MFT N/A 121 |

Net lbs/MFT N/A 709 |

| A3/0-01UD15GT103X |

Conductor Size AWG/kcmil N/A 3/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.456 |

Neutral Size AWG/kcmil N/A 11 |

Neutral No. of Wires N/A 16 |

Neutral Size N/A 1/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.822 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.902 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.184 |

Neutral lbs/MFT N/A 89 |

Net lbs/MFT N/A 679 |

| A4/0-01UD15GT100X |

Conductor Size AWG/kcmil N/A 4/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.512 |

Neutral Size AWG/kcmil N/A 23 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A Full |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.878 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.958 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.266 |

Neutral lbs/MFT N/A 295 |

Net lbs/MFT N/A 962 |

| A4/0-01UD15GT203X |

Conductor Size AWG/kcmil N/A 4/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.512 |

Neutral Size AWG/kcmil N/A 15 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 2/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.878 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.958 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.266 |

Neutral lbs/MFT N/A 193 |

Net lbs/MFT N/A 869 |

| A4/0-01UD15GT112X |

Conductor Size AWG/kcmil N/A 4/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.512 |

Neutral Size AWG/kcmil N/A 12 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 1/2 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.878 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.958 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.266 |

Neutral lbs/MFT N/A 154 |

Net lbs/MFT N/A 834 |

| A4/0-01UD15GT103X |

Conductor Size AWG/kcmil N/A 4/0 |

No of Wires N/A 19 |

Nominal Diameter (in) N/A 0.512 |

Neutral Size AWG/kcmil N/A 8 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 1/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.878 |

TRXLPE Insulation Maximum Diameter (in) N/A 0.958 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 60 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.266 |

Neutral lbs/MFT N/A 103 |

Net lbs/MFT N/A 787 |

| A250-01UD15GT103X |

Conductor Size AWG/kcmil N/A 250 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.558 |

Neutral Size AWG/kcmil N/A 19 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 2/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.924 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.004 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.372 |

Neutral lbs/MFT N/A 244 |

Net lbs/MFT N/A 1036 |

| A250-01UD15GT103X |

Conductor Size AWG/kcmil N/A 250 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.558 |

Neutral Size AWG/kcmil N/A 14 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 1/2 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.924 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.004 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.372 |

Neutral lbs/MFT N/A 180 |

Net lbs/MFT N/A 977 |

| A250-01UD15GT103X |

Conductor Size AWG/kcmil N/A 250 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.558 |

Neutral Size AWG/kcmil N/A 10 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 1/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.924 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.004 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.372 |

Neutral lbs/MFT N/A 129 |

Net lbs/MFT N/A 930 |

| A250-01UD15GT103X |

Conductor Size AWG/kcmil N/A 250 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.558 |

Neutral Size AWG/kcmil N/A 8 |

Neutral No. of Wires N/A 16 |

Neutral Size N/A 1/6 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 0.924 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.004 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.346 |

Neutral lbs/MFT N/A 65 |

Net lbs/MFT N/A 846 |

| A350-01UD15GT203X |

Conductor Size AWG/kcmil N/A 350 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.661 |

Neutral Size AWG/kcmil N/A 16 |

Neutral No. of Wires N/A 12 |

Neutral Size N/A 2/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.027 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.107 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.509 |

Neutral lbs/MFT N/A 326 |

Net lbs/MFT N/A 1301 |

| A350-01UD15GT203X |

Conductor Size AWG/kcmil N/A 350 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.661 |

Neutral Size AWG/kcmil N/A 20 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 1/2 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.027 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.107 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.475 |

Neutral lbs/MFT N/A 257 |

Net lbs/MFT N/A 1202 |

| A350-01UD15GT103X |

Conductor Size AWG/kcmil N/A 350 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.661 |

Neutral Size AWG/kcmil N/A 13 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 1/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.027 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.107 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.475 |

Neutral lbs/MFT N/A 167 |

Net lbs/MFT N/A 1120 |

| A350-01UD15GT102X |

Conductor Size AWG/kcmil N/A 350 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.661 |

Neutral Size AWG/kcmil N/A 11 |

Neutral No. of Wires N/A 16 |

Neutral Size N/A 1/6 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.027 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.107 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.449 |

Neutral lbs/MFT N/A 89 |

Net lbs/MFT N/A 1021 |

| A500-01UD15GT112X |

Conductor Size AWG/kcmil N/A 500 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.789 |

Neutral Size AWG/kcmil N/A 23 |

Neutral No. of Wires N/A 12 |

Neutral Size N/A 2/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.155 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.235 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.667 |

Neutral lbs/MFT N/A 469 |

Net lbs/MFT N/A 1693 |

| A500-01UD15GT112X |

Conductor Size AWG/kcmil N/A 500 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.789 |

Neutral Size AWG/kcmil N/A 18 |

Neutral No. of Wires N/A 12 |

Neutral Size N/A 1/2 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.155 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.235 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.667 |

Neutral lbs/MFT N/A 367 |

Net lbs/MFT N/A 1600 |

| A500-01UD15GT112X |

Conductor Size AWG/kcmil N/A 500 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.789 |

Neutral Size AWG/kcmil N/A 12 |

Neutral No. of Wires N/A 12 |

Neutral Size N/A 1/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.155 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.235 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.667 |

Neutral lbs/MFT N/A 245 |

Net lbs/MFT N/A 1488 |

| A500-01UD15GT103X |

Conductor Size AWG/kcmil N/A 500 |

No of Wires N/A 37 |

Nominal Diameter (in) N/A 0.789 |

Neutral Size AWG/kcmil N/A 10 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 1/6 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.155 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.235 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.633 |

Neutral lbs/MFT N/A 129 |

Net lbs/MFT N/A 1343 |

| A750-01UD15GT103X |

Conductor Size AWG/kcmil N/A 750 |

No of Wires N/A 61 |

Nominal Diameter (in) N/A 0.968 |

Neutral Size AWG/kcmil N/A 17 |

Neutral No. of Wires N/A 10 |

Neutral Size N/A 1/2 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.346 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.426 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.900 |

Neutral lbs/MFT N/A 551 |

Net lbs/MFT N/A 2198 |

| A750-01UD15GT103X |

Conductor Size AWG/kcmil N/A 750 |

No of Wires N/A 61 |

Nominal Diameter (in) N/A 0.968 |

Neutral Size AWG/kcmil N/A 18 |

Neutral No. of Wires N/A 12 |

Neutral Size N/A 1/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.346 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.426 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.858 |

Neutral lbs/MFT N/A 367 |

Net lbs/MFT N/A 1973 |

| A750-01UD15GT102X |

Conductor Size AWG/kcmil N/A 750 |

No of Wires N/A 61 |

Nominal Diameter (in) N/A 0.968 |

Neutral Size AWG/kcmil N/A 14 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 1/6 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.346 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.426 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.824 |

Neutral lbs/MFT N/A 180 |

Net lbs/MFT N/A 1758 |

| A750-01UD15GT102X |

Conductor Size AWG/kcmil N/A 750 |

No of Wires N/A 61 |

Nominal Diameter (in) N/A 0.968 |

Neutral Size AWG/kcmil N/A 15 |

Neutral No. of Wires N/A 16 |

Neutral Size N/A 1/12 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.346 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.426 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.798 |

Neutral lbs/MFT N/A 121 |

Net lbs/MFT N/A 1670 |

| A1000-01UD15GT103X |

Conductor Size AWG/kcmil N/A 1000 |

No of Wires N/A 61 |

Nominal Diameter (in) N/A 1.117 |

Neutral Size AWG/kcmil N/A 22 |

Neutral No. of Wires N/A 10 |

Neutral Size N/A 1/2 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.495 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.575 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 2.049 |

Neutral lbs/MFT N/A 713 |

Net lbs/MFT N/A 2683 |

| A1000-01UD15GT103X |

Conductor Size AWG/kcmil N/A 1000 |

No of Wires N/A 61 |

Nominal Diameter (in) N/A 1.117 |

Neutral Size AWG/kcmil N/A 23 |

Neutral No. of Wires N/A 12 |

Neutral Size N/A 1/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.495 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.575 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 2.007 |

Neutral lbs/MFT N/A 469 |

Net lbs/MFT N/A 2399 |

| A1000-01UD15GT102X |

Conductor Size AWG/kcmil N/A 1000 |

No of Wires N/A 61 |

Nominal Diameter (in) N/A 1.117 |

Neutral Size AWG/kcmil N/A 12 |

Neutral No. of Wires N/A 12 |

Neutral Size N/A 1/6 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.495 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.575 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 2.007 |

Neutral lbs/MFT N/A 245 |

Net lbs/MFT N/A 2194 |

| A1000-01UD15GT112X |

Conductor Size AWG/kcmil N/A 1000 |

No of Wires N/A 61 |

Nominal Diameter (in) N/A 1.117 |

Neutral Size AWG/kcmil N/A 10 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 1/12 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.495 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.575 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 1.973 |

Neutral lbs/MFT N/A 129 |

Net lbs/MFT N/A 2041 |

| A1250-01UD15GT103X |

Conductor Size AWG/kcmil N/A 1250 |

No of Wires N/A 61 |

Nominal Diameter (in) N/A 1.251 |

Neutral Size AWG/kcmil N/A 18 |

Neutral No. of Wires N/A 10 |

Neutral Size N/A 1/3 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.641 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.721 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 2.195 |

Neutral lbs/MFT N/A 583 |

Net lbs/MFT N/A 2917 |

| A1250-01UD15GT102X |

Conductor Size AWG/kcmil N/A 1250 |

No of Wires N/A 61 |

Nominal Diameter (in) N/A 1.251 |

Neutral Size AWG/kcmil N/A 15 |

Neutral No. of Wires N/A 12 |

Neutral Size N/A 1/6 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.641 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.721 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 2.153 |

Neutral lbs/MFT N/A 306 |

Net lbs/MFT N/A 2598 |

| A1250-01UD15GT112X |

Conductor Size AWG/kcmil N/A 1250 |

No of Wires N/A 61 |

Nominal Diameter (in) N/A 1.251 |

Neutral Size AWG/kcmil N/A 12 |

Neutral No. of Wires N/A 14 |

Neutral Size N/A 1/12 |

TRXLPE Insulation Nominal Thickness (mils) N/A 175 |

TRXLPE Insulation Minimum Diameter (in) N/A 1.641 |

TRXLPE Insulation Maximum Diameter (in) N/A 1.721 |

Encap XLPE Jacket Nominal Thickness (mils) N/A 90 |

Encap XLPE Jacket Nominal Diameter (in) N/A 2.119 |

Neutral lbs/MFT N/A 154 |

Net lbs/MFT N/A 2408 |